Extrusion is a moulding process for the synthesis and recycling of plastics with complex dependencies on material properties and process conditions. The selection of setting variables and troubleshooting in production are always costly and time-consuming. In particular, there is a lack of measurement technology and accessibility to fully monitor the materials in terms of composition, retention time and temperature. As a solution, the joint SME project aims to develop an AI assistance system for the spatially resolved visualisation of the material flow and the prediction of processes in extrusion lines. The aim is real-time prediction of the mass distribution in the melt channel for direct control of the extrusion processes.

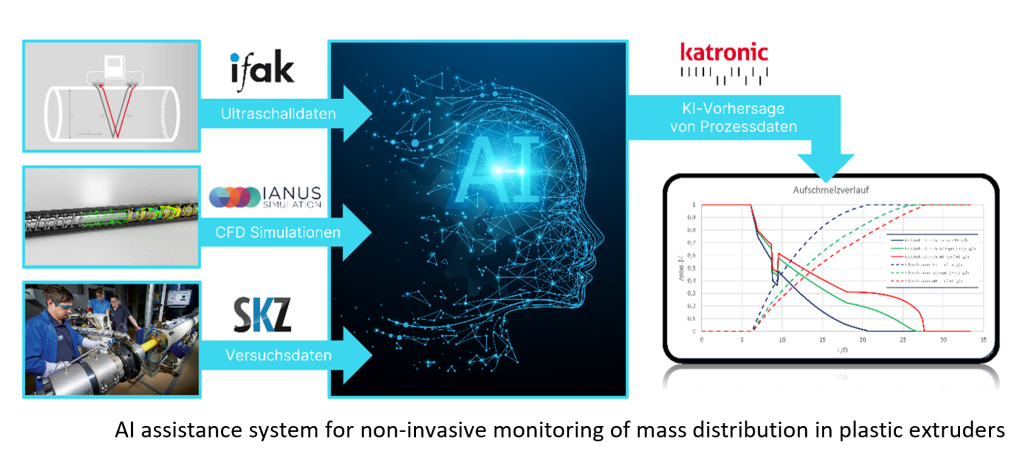

Specifically, the system consists of a simulation AI that provides predictions about the residence time and melting behaviour based on non-invasive ultrasonic data recorded at the extruder. The ultrasonic measurement can be retrofitted in systems and provides data on the mass flow. In combination with conventional data from the extrusion process, a simulation model (CFD) is used to map the melting and flow conditions for different materials and extruder geometries with the help of trained AI. The aim is to provide the operator with a live visualisation of the dwell time and melting process of plastics in extruders and thus significantly improve the application and efficiency of extruders.

The ifak research institute is working closely with Katronic to develop the ultrasound measurement method and the necessary algorithms for AI-capable evaluation and processing of the data. The SME IANUS is modelling the flow process and the SKZ research institute is supporting the implementation and development of the overall system on an industrial prototype system.

Associated partners:

- 102 Extrusion Technologies GmbH

- MAINCOR Rohrsysteme GmbH & Co. KG